Which EWP Is Right For Your Project?

- magda

by Daniel Green

There’s no doubt that the humble work platform has made our collective lives far easier and safer. Gone are the extension ladders and forklift work boxes of old. Yep, Elevated Work Platforms have revolutionised the way we think about working at height.

But which machine is best for you? Well that would depend on what you’re trying to achieve, what working environment you’re in, the ground conditions, if there’s live power nearby and what ticket/s you have.

Unfortunately google doesn’t yield much on this topic. So with luck right now you’re reading the definitive guide. Read on.

Some History

The story goes that Canadian Walter E. Thornton Trump invented the EWP in the 1950’s. He wanted it to be known as a giraffe, but due to their frequent use in orchards the name cherry picker stuck. Soon after different needs drove innovation and new variations began to pop up. Over the coming decades the number of EWP varieties expanded to what we see today.

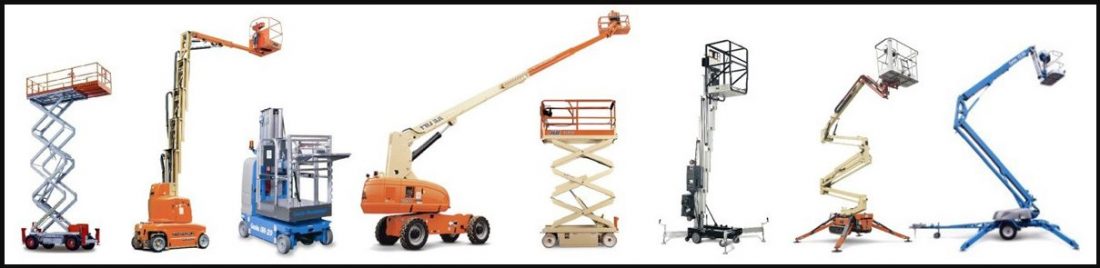

Some Variations

Cherry Pie

Originally named for its use for literally picking cherries, this mostly truck mounted variety has the indisputable position of being first. Powered by a hydraulic system utilising a PTO that borrows power from the donor truck’s engine, they were the primary tool for outdoor work at height for decades until the advent of the boom lift in the 1980’s. Stability came in the form of outriggers mounted to the truck. These adjustable hydraulic legs increased the truck’s ‘base’, allowing the basket to reach further from the machine’s centre of gravity greatly decreasing the risk of toppling. Remaining popular with electricity linesmen, the cherry picker is still in use today.

Advantages: good for use on uneven ground due to adjustable outriggers, long reach, stability due to large base and heavy truck weight, doesn’t need to be delivered to site.

Disadvantages: long boom design requires large swing zone, external use only due to requirement of truck engine to run during operation, small basket.

Best use: outside on straightforward tasks with plenty of room and good visibility.

Scissor Lifts

Soon after the cherry-picker hit the market, operators saw that the lengthy boom design needed bulk room and so their collective cogs began whirring for a more compact version. The scissor lift was born. Battery power in the 1960’s has nothing on today’s Li-Ion technology so the first generation of scissors were diesel powered. Utilising a series of swivelling arms much like a series of scissors in a row, this type means you can float the basket far into the air. Eventually battery technology caught up, meaning they could be used in confined spaces without risk of suffocation from the carbon monoxide caused by internal combustion engines.

Advantages: smaller spaces accessible due to compact design, internal operation due to battery power, larger basket allows for more tools and working space.

Disadvantages: you have to be within reach of the works due to the lack of a boom, floor must be flat and level due to arguably unstable design, needs to be delivered to site.

Best use: indoors on flat level surfaces.

Boom Lifts

Within a couple of years of the cherry picker invention innovators saw the need for a self-propelled version. The boom lift was born. While this new WP was better suited to more compact environments, it still suffered the large swing radius required by its concertina boom design.

Advantages: for use in spaces bigger than a scissor lift but smaller than a cherry picker, use indoors due to battery power, long and high reach, large basket.

Disadvantages: not compact due to boom design, small basket, needs to be delivered to site.

Best use: indoors on flat level surfaces and lots of space to maneuver.

Knuckle Lifts

When you say the acronym ‘EWP’ this is what people generally picture. Knuckles have multiple, independently articulating joints that allow for extreme maneuverability. You can drive fore and aft, steer, slew the body, lift and lower the primary boom, lift and lower the secondary boom [this has a different movement outcome than the primary boom], telescope the third boom in and out, jib the fourth boom up and down, slew the basket side to side, and tilt the basket up and down. It wasn’t until technology caught up in the late 1990’s that these machines were even possible.

Advantages: you can reach almost anywhere, compact design.

Disadvantages: feels unstable at height due to more articulation joints, operation can be confusing due to more maneuverability, smaller basket, needs to be delivered to site.

Best use: when you have to get high but there’s obstacles everywhere.

Trailers

The advantage of these EWP’s is that they don’t need to be delivered by a tilt-tray, the disadvantage is that they’re not self-propelled, meaning they can’t be driven. If you want them moved you have to bring the basket down, maneuver the tow vehicle, climb back in the basket and boom up. They are very stable though because the chassis has outriggers like the original cherry picker.

Advantages: stable due to large base and outriggers, decent reach, doesn’t need to be delivered to site.

Disadvantages: moving the unit needs to be done from the ground, smaller basket.

Best use: small jobs with plenty of room.

Unders and Overs

In Australia, EWP’s are divided into two categories: under 11m and over 11m. This means that their reach [where the basket can get to] is either under or over 11m from the centre of the turntable. In either case, in the land down under, before you operate any kind of EWP you need some training and competence verification.

RIIHAN301E – under 11m

To swing baby booms you need this qualification. It’s a one day course that involves detailed theory & practical training & testing. Training units include pre-starts, hazard identification and machine operation. This means you can operate any elevated work platform of any description with a reach of less than 11m. 11 metres is still quite high. That’s three-and-a-half floors of 10ft ceilings. Four-and-a-half floors at 2.4m ceilings.

High Risk Work License – over 11m

The beauty of this ticket is that the training is very comprehensive. It covers many more aspects of operation than the under 11 qualification due to the greater operational risk.

Entitled TLILIC0005, you get an HRW licence to operate at the end of it, which is a far more serious obligation than the < 11m qual. But just because you can operate larger machines doesn’t mean you automatically can operate under 11m ones. You will still need the < 11m training. This course runs for two full days. Given that you can go and jump in a 50m boom pretty much straight away, a strict two day course is probably a good thing.

Ready or Not

So there you have it. The ups and down and ins and outs of EWPs. For more information on EWP licensing Perfect uses Health and Safety Advisory in Emu Plains. Give ‘em a call!